Innovation and Excellence at the Heart of our Work

In business since 1996, Prolifik is a Quebec-based SMB specializing in the design and high-volume manufacturing of galvanized steel ventilation ducts.

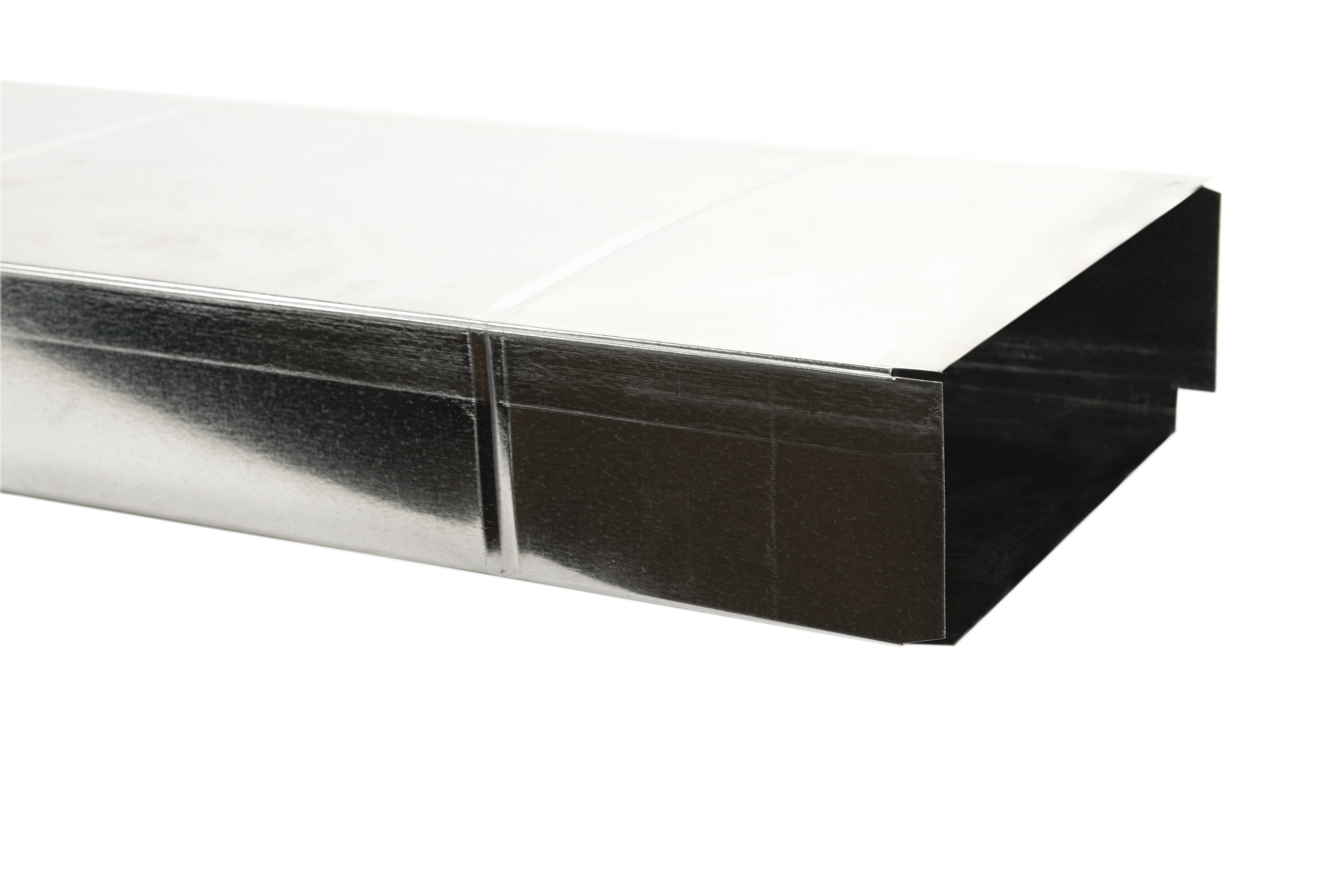

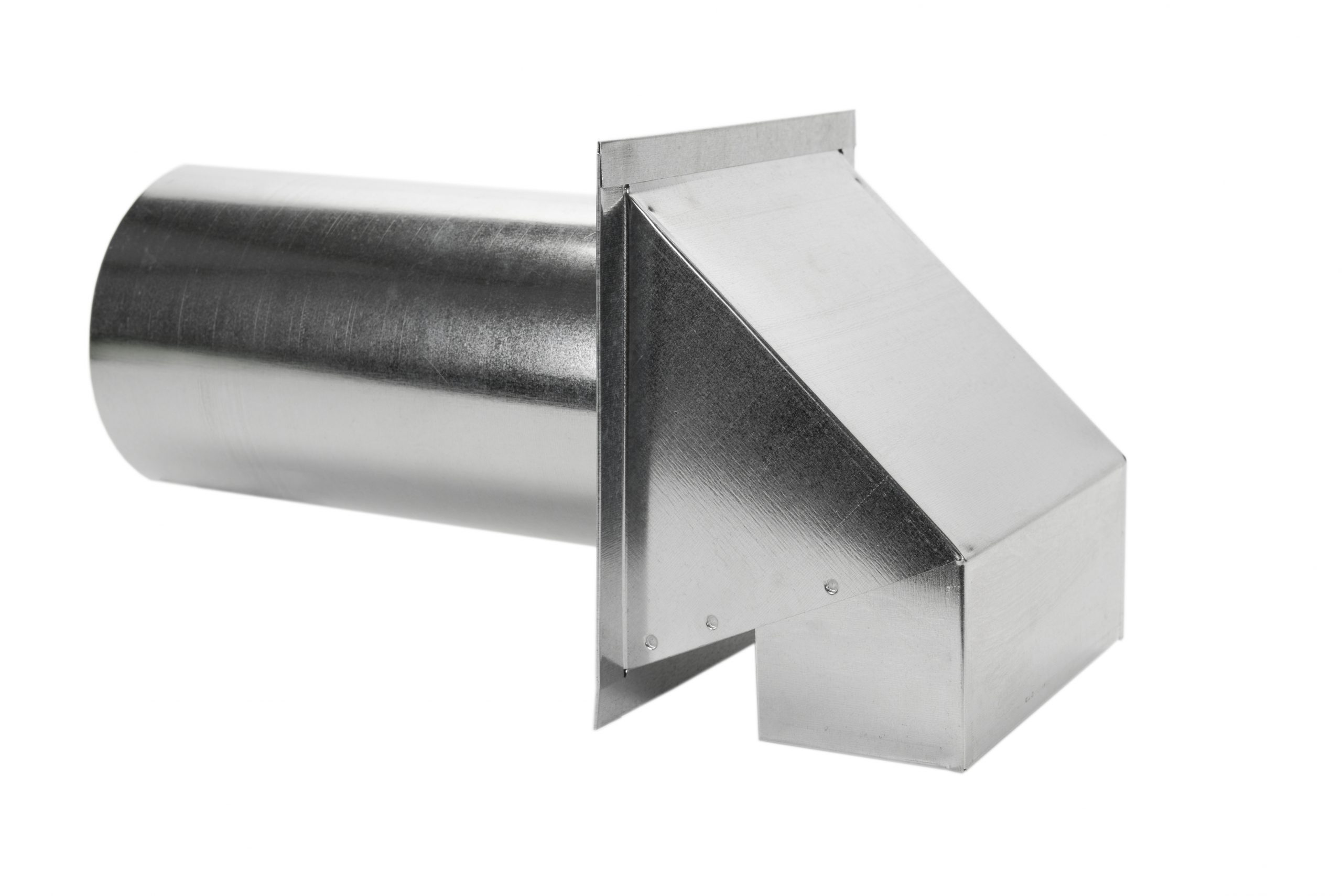

Our mission? To focus on innovative, reliable and high-performance design to deliver high-precision parts to the residential, commercial and industrial markets.

Company 4.0

Technology and Precision of Execution

At Prolifik, our state-of-the-art facilities allow us to manufacture our parts consistently, accurately and quickly.

Our ever-evolving manufacturing processes rely on constantly updated, state-of-the-art equipment and the latest Industrial Revolution 4.0 tools (Poka, Worximity ans PowerBI). Meticulously manufactured and easy to install, our ventilation ducts are recognized for their efficiency and durability.

Our continuous training system allows us to offer our employees comprehensive training on our most recent equipment and technological tools.

Our History

A Journey of Success and Innovation

For more than 25 years, Prolifik has made it a commitment to keep up to date and to focus on innovation and quality.

Our highly efficient technological equipment allows for the sustained production of the most accurate and reliable ventilation ducts in the industry.

News that underline

our 25 years of business

Join our team

A Job at Prolifik Is a Winning Deal!